Simulation software 'gPROMS Process'

For process development, optimal plant design, and operational optimization studies! Simulators for the oil, gas, and chemical industries.

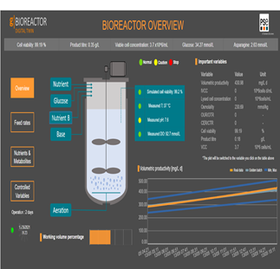

In plant design, equipment sizing, process consideration, and operational optimization, PSE believes that existing process simulators still have room for improvement in terms of convergence for obtaining numerical solutions, constraints of processes they can handle, and customization of process models (model extensibility). The process simulation software developed to meet the needs for more advanced and value-added process plant design and optimization is 'gPROMS Process'. 【Features】 * Libraries for specific applications * Creation of flow sheets using Drag & Drop * High-precision custom model creation and editing functions using gPROMS language * Changes in settings within the same environment from steady-state simulation models to dynamic simulation models * Powerful optimization solution search and analysis functions * Global System Analysis (GSA) * High-Performance Computing (HPC) ★ You can view two "case study materials" available for download. These include examples of achieving high-value product offerings and cost reduction through batch process optimization, as well as successful cases of cost reduction through the optimization of entire plants.

- Company:シーメンス株式会社 gPROMS ポートフォリオ

- Price:Other